I bring the athlete mentality to design. Everything I learn on the court I try to apply to the design game and vice versa. Some of the best life lessons are when you’re at the rawest and gotta trust in your squad. I’ll stay dedicated to that. Always.

This project has been intense. I purchased a 3D Printer for part creation during school. Brackets, sliders, mounts were mostly what was being printed, but in the back of my mind I wanted to make my own shoes. I knew that. I just needed to figure out how. Below are some visuals of that how.

Listen, let’s just be plain here. This industry is built on the excellence and greatness of minority athletes only to box those same people out of design and management roles.

Limited space, coupled with a complete lack of available information on where and how to start your own sneaker project, not to mention the exorbitant costs to start up traditionally. It’s clear what the game plan is. Now to break that. I hope this info can be someones guide to replicate similar results.

“No, Hov’ did that

So hopefully you won’t have to go through that”

PLA – The first prints.

Iterations and experiments in form and shape only

Due to size and time limitation, components were split into back and front half – Heel And Toe

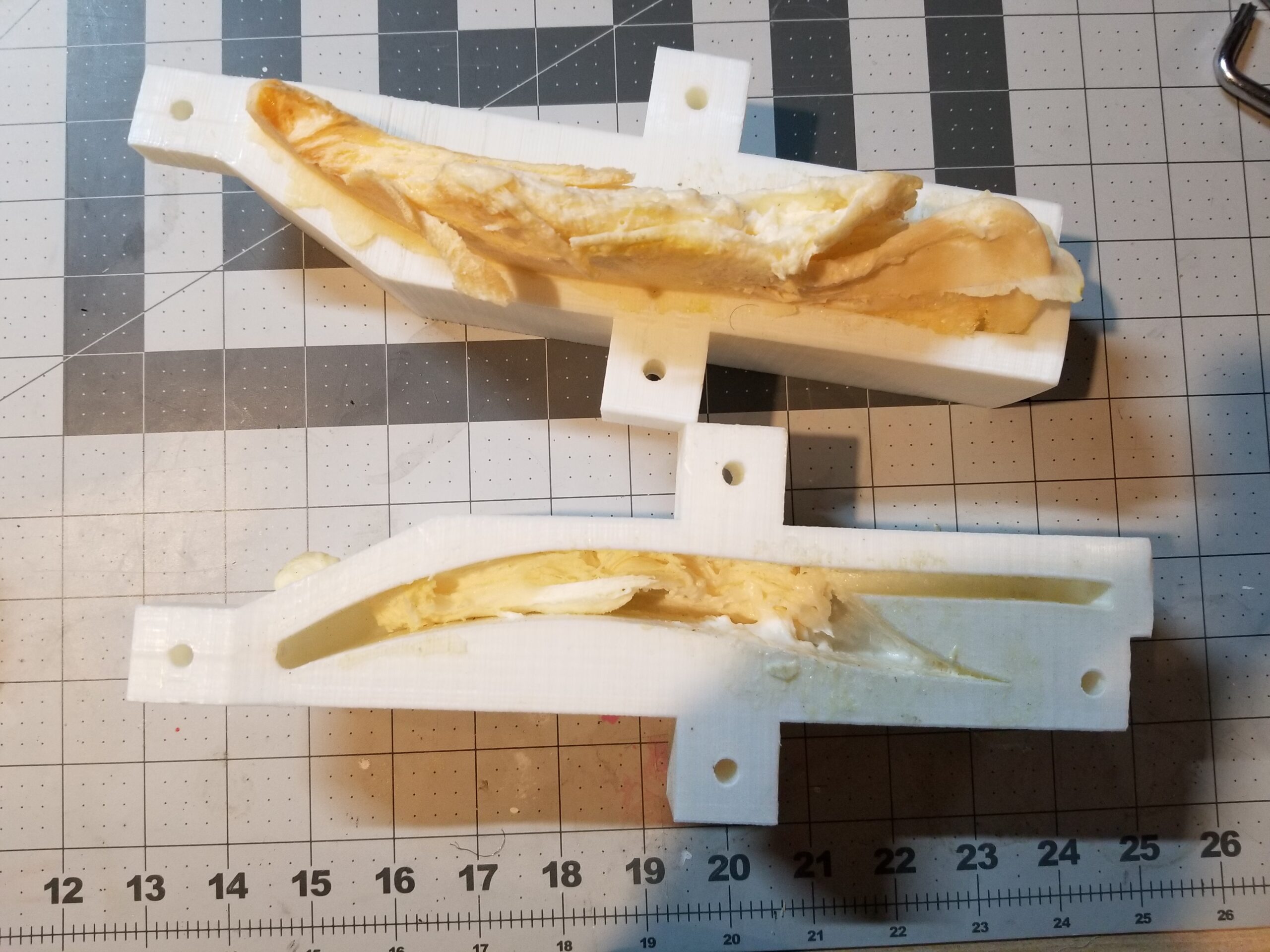

Attempts at injecting foam – 3D Printing Mold for foam.

The AHA! Moment – TPU Printing. Simulating cushion with a Lattice Structure

It was here I had to stop for about six months. I was stuck. The cushion was comfortable, but overall, the shape sucked. This wasn’t the way to go about this.

RESET

And All that for that ugly thing? Naw we ain’t going down like that.

ADD:

Heel Counter

Toe Cap

Change Sole. Too Bulky

Be You.

Low Quality Test Print – 8 Hours

Medium Quality Test Print – 16 Hours – Evidence of hardware issues – Modifications Necessary.

Hardware Modifications

Always free to answer questions. Smash that button in the menu if you have any,

Saw your post in reddit.

Amazing work. I am impressed how you kept at it, and kept innovating.

The use of a sock is genius.

I have wanted to make my own show as well, but my expectations are lower. Something more like crocs. For the beach or the garden.

My feet have a word shadow, so it’s hard to get a shoe that fits.

Thanks for the encouragement, and best of luck!

Any chance of a video of them being used?

This is wild! I am absolutely blown away by this. I think you’re on to something big!

This is amazing! I saw your posts on Reddit and it’s awesome to see the different iterations you took to end up with a workable sole. Where/how did you get the black fabric part for your shoes?

Amazing project, thank you for sharing!

Where did you get the upper part for the shoe? Which printer did you use? How did you create the lattice structure in Fusion 360?

Looking forward to seeing more of your work in the future!

Amazing.

Do you know about IceSL slicer and their polyfoam infill? It’s awesome.